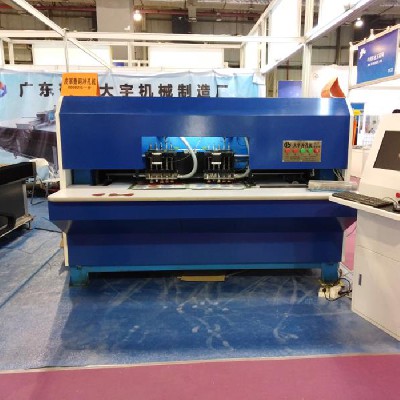

Jiangmen leather punching machine manufacturer tells you how to correctly use automatic punching machines

The first thing we should do is to process the oil pipe standard according to our needs, and the gap standard for processing time. The standard pipe processing is a fixed fixture for processing orientation and other data. The fixture and fixture are tightly fastened by wheels

2. Then we will involve automatic punching machines with artificial intelligence, computer data input processing, pipeline length, number of holes, etc

3. We need an automatic punching machine for the processing mold of the pipeline, and then fix the clamp

4. Start the program to start stamping, and the artificial intelligence system of the automatic punching machine will automatically punch out a piece of pipe at once according to the instructions of the punching machine and data processing, and produce cutting and punching

5. If the product suddenly encounters a card or shortage of materials during the production and processing process, the artificial intelligence system will prompt an alarm and work agilely intermittently. This time, we will press the sudden interruption switch to avoid secondary damage to the equipment

6. If the cutting tools used in the production and manufacturing processes are not sharp, the artificial intelligence system of the automatic punching machine will provide timely replacement for machine operators who pay attention to punching

We need to learn how to identify the quality of automatic punching machine molds. Verify through practice that the products produced by the mold meet the company's product quality requirements, and then acknowledge that the automatic stamping function cannot be input into production and delivered for use

2. During the debugging process of stamping molds, the qualified molds in the factory are controlled and adjusted through computers. In order to master the specific functions of stamping molds, how to characterize products, and the methods of laws and regulations, it is necessary to understand the process of mass production of these solutions in the future and provide the conditions for the project

3. The debugging process of automatic punching machine molds can help with the planning of some more complex or demanding automatic punching machine molds

Article source: Jiangmen perforating machinewww.hslichuang.com

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline