Introduction and Application of Jiangmen Leather Punching Machine

Equipment Introduction

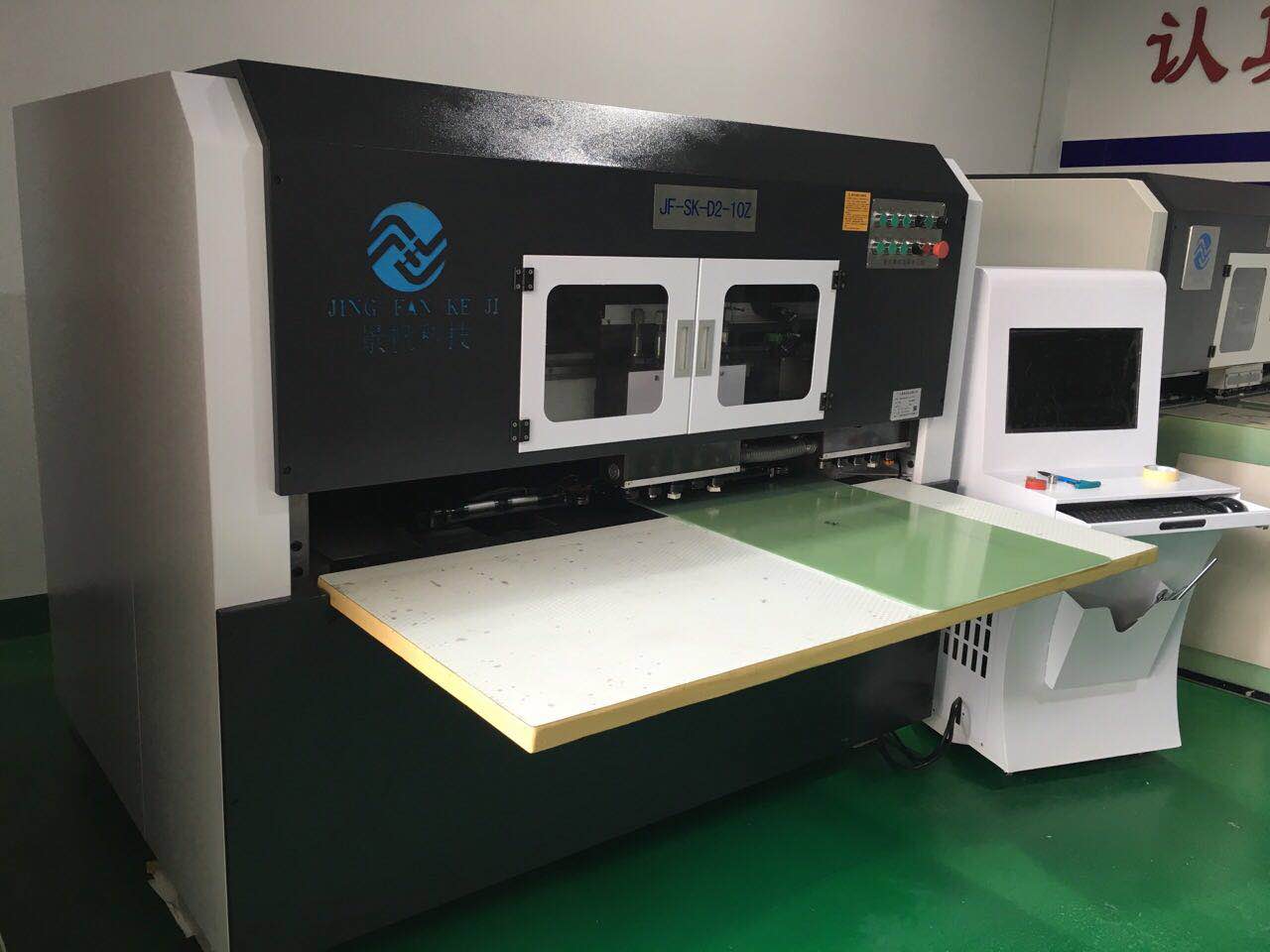

The leather punching machine adopts advanced numerical control skills, electronic skills, and software skills.

Numerical control skills are one of the core contents of advanced manufacturing skills, and are moving towards high-speed, high-precision, multifunctional, intelligent, systematic, and high reliability. The CNC leather punching machine utilizes CNC skills to actively position, layout, scan, and move, with simple and convenient operation; And its mold can produce various patterns, and can also be simulated and imitated by computer. The mechanical leather punching machine utilizes modern technology and years of accumulated punching mechanical skills, with high operational scale and work efficiency.

In terms of electronic skills, the leather punching machine uses a high-speed SOC microcontroller, which can complete real-time control.

In addition, in terms of software skills, interactive human-machine interfaces are selected for easy and simple operation, and reliable operation.

use

Leather punching machine is suitable for leather, cowhide, sheepskin, artificial leather, plastic PU、EVA、PVC, Punching processing of various fabrics, papers, leather accessories, shoe uppers, decorative pieces, window fabrics, car leather chairs, etc., widely used in industries such as automotive parts (breathable seat cushions), luggage and handbags, stationery, shoes, breathable materials, advertising paper products, etc.

Article source: Jiangmen Leather Punching Machinehttp://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline