What are the working principles of mechanical leather punching machines analyzed by leather punching machine manufacturers

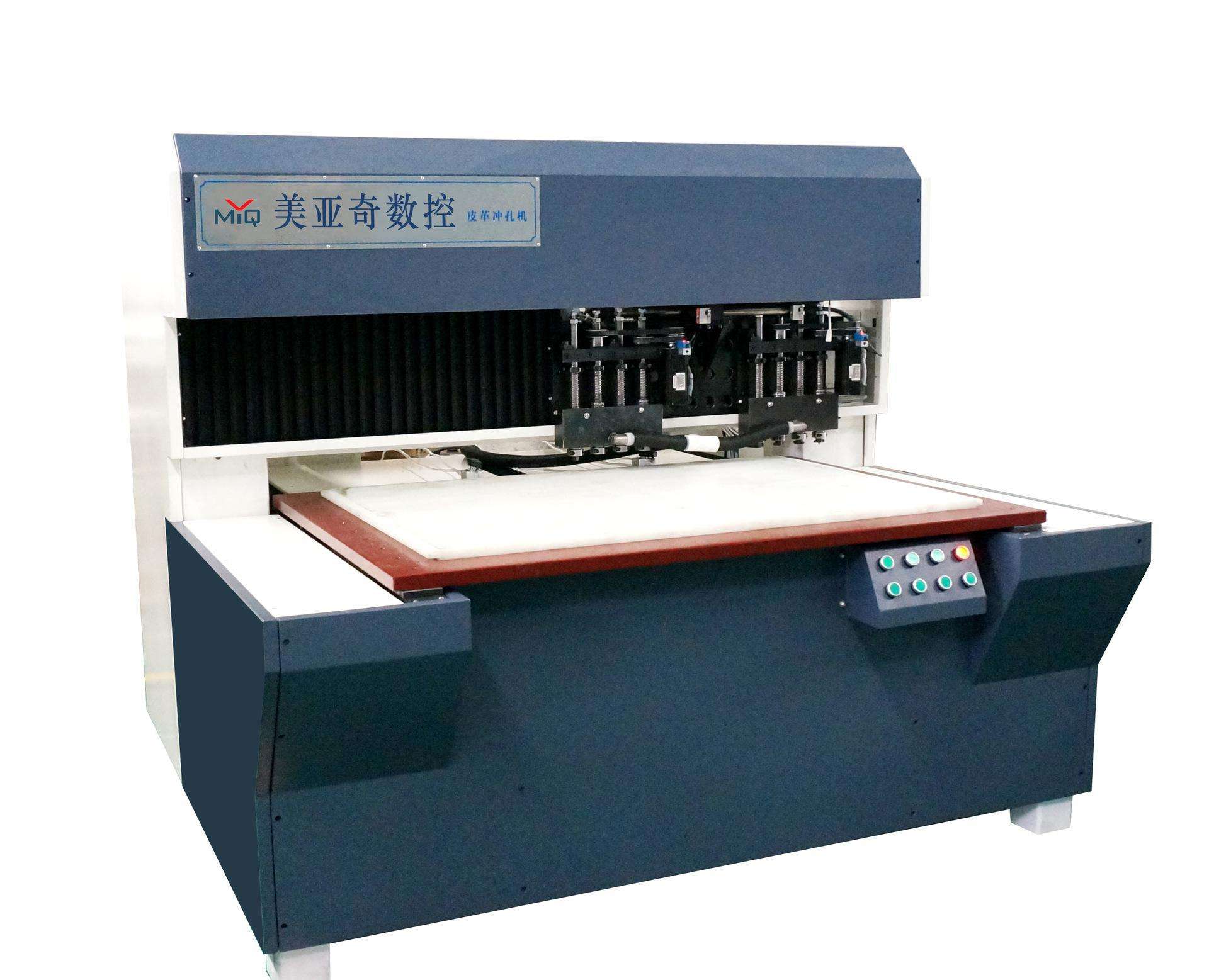

1、 The leather punching machine adopts advanced numerical control skills, electronic skills, and software skills.

1. Numerical control skills are one of the core contents of advanced manufacturing skills, and are being developed towards high-speed, high-precision, multifunctional, intelligent, systematic, and high reliability.

In terms of electronic skills, the Lijin leather punching machine uses a high-speed SOC microcontroller, which can achieve real-time control. 3. In terms of software skills, interactive human-machine interfaces are selected, which are easy to operate and reliable to run.

2、 Mechanical characteristics of leather punching machine

1. Whole machine tempering treatment

2. The spindle is processed using a ten meter large CNC lathe, and the main machine is machined into shape in one go using a large gantry milling machine to ensure mechanical accuracy

3. The mechanical weight is 8.5 tons, which can better ensure the stability of the machinery

4. Using magnetic powder clutch for material collection can better ensure accurate and orderly material collection

5. The bearing adopts a copper sleeve structure of high-speed punching machine to ensure precise mechanical guidance, high wear resistance, self-lubricating, and high precision

6. The leather punching machine uses circulating cooling oil internally to ensure sufficient lubrication, reduce temperature to prevent annealing, and improve the hardness and wear resistance of the guide column

3、 Other characteristics of leather punching machine

1. This machine can punch holes and heat embossing, making it versatile.

2. Efficient production, fast speed, suitable for large-scale production.

3. The patterns are diverse and beautiful.

Leather punching machine: mainly suitable for leather (leather), shoe uppers, fabrics, sponges, cardboard PE、PVC、EVA、 Large area punching processing of various materials such as artificial leather, genuine leather, foam, single transparent adhesive, car seat cushions, non-woven fabrics, etc. So, leather punching machine is also known as leather punching machine, PVC punching machine, PE punching machine, EVA punching machine, sponge punching machine, single penetration adhesive punching machine, fabric punching machine, mother child punching machine, shoe upper punching machine, etc.

Article source: Leather punching machine manufacturerhttp://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline