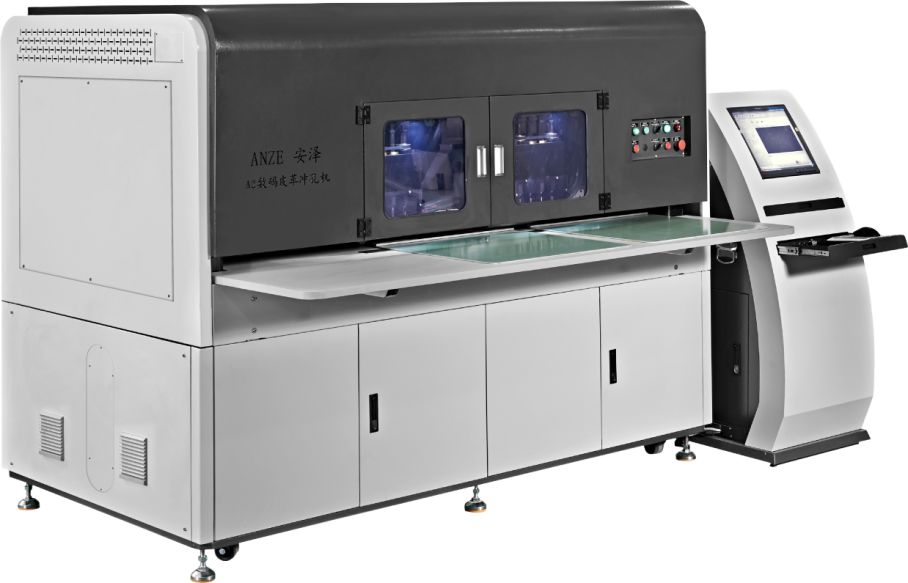

How to distinguish the advantages and disadvantages of digital leather punching machines and laser leather punching machines

The principle of CNC leather punching machine: It uses the rotation radius of the crankshaft to achieve mechanical reciprocating motion, forming the function of punching various required hole shapes on products such as leather, fabric, paper, foam, thin metal, PVC sheet, and various films. Laser leather punching machine: Laser processing uses the energy of light to converge through a lens and reach a high energy density at the focal point, relying on the photothermal effect for processing. Comparison between the two: CNC leather punching is environmentally friendly, odorless during processing, and the holes in the processed products are consistent in size, with edges that do not turn yellow or harden. Avoiding the drawbacks of laser punching.

One is a soft material mechanical punch with a fixed grinding tool head, and the other is a more sensitive laser machine for cutting. Each has its own strengths and weaknesses.

Punching machines are more efficient when used for products with consistent quantities on belts, but special drawings need to be made and customized cutting heads require a certain cycle time

Laser cutting machines are known for their sensitivity, but in terms of leather cutting, the cut surface is not as beautiful as when a new blade is used. This is because lasers, which are non touch laser energy processing, can gather extremely high energy on the cut surface, causing the leather to turn a bit yellow and making PU more ambitious.

The advantage of using laser to make those red soled nail shoes is quite obvious. The quantity is not large and the cut surface cannot be investigated. Using masking paper to cut open can reach the intact leather surface.

Article source: Jiangmen Leather Punching Machinehttp://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline