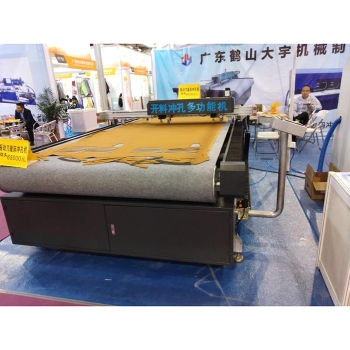

Leather vibration knife cutting punching machine meets the development needs of the "manufacturing industry"

The contemporary composite mechanical and machining skills, with the continuous improvement of numerical control automation skills, have gradually taken shape and become stable. One machine tool can complete various types of cutting work and meet various production requirements. This production method significantly increases production power and promotes the innovation of cutting methods. The development of leather vibration knife cutting and punching machines seems to be moving towards a composite direction, simplifying the cutting process and reducing the resulting rated cost.

The modern mechanical processing and manufacturing industry's requirements for the quality and accuracy of flexible material cutting are constantly increasing, and the functional requirements for leather vibration knife cutting and punching machines are also constantly improving. The leather vibration knife cutting and punching machine has the characteristics of fast cutting speed, good accuracy and cutting quality, but these characteristics need to be continuously expanded to meet the needs of the market.

In addition, the comprehensive intelligent development of leather vibration knife cutting and punching machines is also a major trend. Manual cutting is far less precise than CNC cutting, and the same applies to working power. Through the control of the leather vibration knife cutting and punching machine by the computer, the working method of the leather vibration knife cutting and punching machine has shifted towards intelligence, which is also one of the serious changes in the leather vibration knife cutting and punching machine. Comparing the functional features of several commonly used CNC leather cutting machines, the leather vibration knife cutting punching machine has a relatively complete function. The application of graphic cutting code automatic conversion software, the common advantage of cutting leather, and the low investment cost have made leather vibration knife cutting and punching machines among the top in the current cutting industry.

The development momentum of precision machining industry is gradually improving, and the requirements for high-precision machinery are becoming more stringent. In the development direction of leather vibration knife cutting and punching machines, the proportion of skill research is quite large. The processing accuracy has gradually improved from the wire level to the micrometer level. Under the premise of meeting the needs of the era, products and skills will gradually be recognized and promoted, so the comprehensive intelligence of CNC leather cutting skills is also an important aspect of its development.

Computer networking and communication and collaboration between enterprises are necessary ways to promote the rapid development of CNC skills. Enterprises should maintain normal communication and exchange, analyze the market situation, and use this as a basis to upgrade and transform CNC skills. Computer networking is more conducive to skill exchange and promotes the skill transformation of CNC cutting and starting machines.

The leather vibration knife cutting and punching machine is suitable for cutting any flexible material, with high cutting accuracy and no thermal deformation, making it a relatively environmentally friendly cutting method. The leather vibration knife cutting and punching machine will be the direction for the development of CNC cutting machines.

The article comes from the leather vibration knife cutting punching machine:http://www.hslichuang.com/

-

10-14

Leather cutting machine: How to choose fiber laser cutting machine

When choosing a fiber laser cutting machine, it is important to check the cutting precision, which can generally be controlled between 0.1 millimeters and 0.2 millimeters. In the process of actual inc

-

10-13

Leather cutting machine: the influence of cutting oxygen pressure on cutting speed

When using CNC flame cutting machine, there are many factors that affect the gas flame cutting process, among which cutting oxygen flow plays a crucial role in gas flame cutting. Cutting open the oxyg

-

10-12

Leather cutting machine: Characteristics of leather cutting machine

Characteristics of leather cutting machineThere are still many manufacturers on the market who make leather cutting machines. So, among the many manufacturers, how to choose a suitable equipment manuf

-

10-11

Digital leather punching tells you the characteristics of CNC punching machines

The operation and monitoring of the CNC punching machine are all completed in this CNC unit, which is the brain of the CNC punching machine. Compared with ordinary punching machines, CNC punching mach

National Service Hotline

National Service Hotline