-

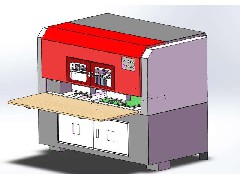

What are the effects of digital leather punching machine on shaping shoe uppers

2025-08-16 1312

1. Combine the three major skills into one; Simultaneously shaping, fitting, and ironing the sewn shoe upper to achieve a perfect combination with the last.After shaping, the shoe upper no longer has

-

How to improve the safety of digital leather punching machine operation

2025-08-15 1607

In general, enterprises will select the type of digital leather punching machine equipment based on the nature of the process to be completed, batch size, geometric dimensions of the workpiece, and ac

-

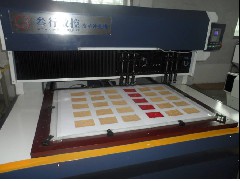

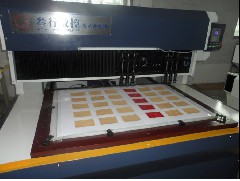

What are the characteristics of digital leather punching machines

2025-08-14 1321

CNC (digital) leather punching machine can also be called leather bag punching machine, luggage punching machine; The various fancy appearances are particularly eye-catching to customers. Scale of was

-

How can the shoe upper punching machine be used in leather and its development prospects

2025-08-12 1393

In daily life, people can no longer live without leather products. Widely used are leather shoes or car leather seat cushions. In the production process of these leather products, there will be a step

-

What are the performance characteristics of vibration knife leather punching machine

2025-08-11 1698

1. Selecting an advanced four axis high-speed motion control system with independent intellectual property rights, the system upgrade and maintenance are not controlled by third parties, and the later

-

The characteristic of using linear guide instead of traditional guide rod in CNC leather punching machine

2025-08-10 1453

The CNC leather punching machine uses linear guide rails instead of traditional guide rods to improve mechanical function and is easy to maintain:1. The structure of the linear guide is simple, the eq

-

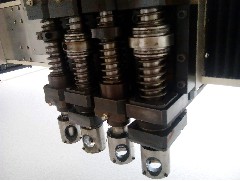

What are the mechanical characteristics of leather punching machines

2025-08-09 1484

Mechanical characteristics of leather punching machine1. Whole machine tempering treatment2. The spindle is processed using a ten meter large CNC lathe, and the main machine is machined into shape in

-

What issues should be noted when operating a CNC leather punching machine

2025-08-08 1401

The first step is to fill the oil tank with hydraulic oil, which usually requires about 120KG (note: it is recommended to use Great Wall brand hydraulic oil)Step 2: Install the mold (note that when in

-

How to distinguish the advantages and disadvantages of digital leather punching machines and laser leather punching machines

2025-08-06 1413

The principle of CNC leather punching machine: It uses the rotation radius of the crankshaft to achieve mechanical reciprocating motion, forming the function of punching various required hole shapes o

-

How to clean the hydraulic punching machine of leather punching machine after disassembly

2025-08-05 1643

After disassembling the hydraulic punching machine, it can be cleaned with cleaning solution. Common cleaning solutions include organic solvents, alkaline solutions, and chemical cleaning solutions. T

National Service Hotline

National Service Hotline